|

|

|

LPG Compressor |

|

|

| Product name : LPG Compressor |

| Item : |

| Details : |

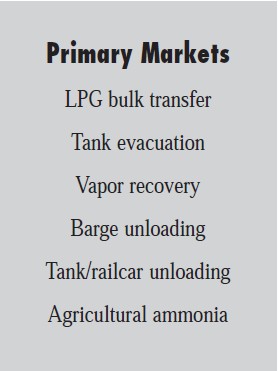

General Information General Information

Compressors are extremely versatile for they can be used to transfer liquids

between tanks, off-load/load out liquids, recover residual vapor, and evacuate

vapors for maintenance purposes. Many LPG piping systems do not provide

ideal NPSH conditions for liquid pumps which causes excessive pump

maintenance. Since compressors are only exposed to vapors, they are not

affected by poor NPSH conditions. Many LPG pressurized tanks such as

railcars and buried tanks have top unloading connections. A compressor can

be the perfect solution for transferring liquids to and from such tanks.

Features Features

- High efficiency valves move more gas volume

The heart of any compressor is its valve assembly and our valves are

specifically designed for non-lubricated gas applications. With precisely

engineered clearances, spring tension, and a special finish, these valves

seat more positively so more gas is moved with each piston stroke.

Our valves offer greater strength, quiet operation, and long life.

- O-Ring seals-head and cylinder

The head and cylinder are sealed with O-rings to ensure positive sealing under

all operating conditions.

- Pressure assisted piston rings for positive seating

Constructed of self-lubricating PTFE, Blackmer's special ring design provides

maximum sealing efficiency with minimal friction wear. The result: peak

performance and extended compressor service life.

- Heavy-duty crankshaft

The ductile iron crankshaft is precision ground with integral counterweights for

smooth, quiet operation. Rifle drilling ensures positive oil distribution to the

wrist pin and connecting rod bearings.

- Pressure lubricated crankcase

A rotary oil pump provides positive oil distribution to all running gear

components for long life and minimal wear.

- Wear-resistant crosshead assemblies

Designed for maximum lubrication and wear resistance.

- Ductile iron pistons

Heavy-duty ductile iron pistons are connected with a single positive locking nut

which eliminates potential problems associated with more complex designs.

- Self-adjusting piston rod seals

Crankcase oil contamination and cylinder blow-by is prevented with loaded

glass-filled PTFE seals which maintain a constant sealing pressure around

the piston rods.

- Ductile iron construction

All pressure parts are of ductile iron for greater resistance to both thermal

and mechanical shock.

PARAMETERS PARAMETERS

| Model |

Capacity |

Power |

Discharge Pressure |

Discharge Temperature |

Weight |

Dimension |

| m3/h |

KW/HP |

Bar G (Max.) |

℃ (Max.) |

Kg |

L*W*H mm |

| 91 |

24 |

5.5/7.5 |

24 |

177 |

390 |

1000*710*865 |

| 291 |

36 |

7.5/10 |

24 |

177 |

410 |

1000*710*865 |

| 491 |

48 |

11/15 |

24 |

177 |

550 |

1100*750*980 |

| 691 |

96 |

22/30 |

24 |

177 |

660 |

1100*750*980 |

| 891 |

150 |

30/40 |

24 |

177 |

750 |

1100*850*1200 |

| 991 |

180 |

37/50 |

24 |

177 |

860 |

1100*850*1200 |

Note:

The parameters are subject to change without prior notice,customer design of special requirement available

Go To Top |

|

|

|